BLTouch is a famous monitor for 3D printers that helps improve how well the bed is levelled. But BLTouch can sometimes fail to check the state of the sensor. There are simple fixes, but they can be annoying.

In this piece, we’ll talk about what klipper BLTouch commands is, what BLTouch failed to verify sensor state means, and the most usual reasons for this problem. This article will help you if you need help. Our information will enable you to resolve the issue and have your 3D printer operating again.

What is BLTouch?

BLTouch is a monitor for 3D printers that helps improve how well the bed is levelled. It sends signals to the printer’s software after testing the bed in several places. The software then uses this information to determine the bed’s height at each point.

The klipper bltouch BLTouch sensor is famous because it is easy to set up and use. Also, it is very exact, which can help you make better pictures.

What does BLTouch failed to verify sensor state mean?

The BLTouch failed to verify the sensor state error message, which means that the BLTouch sensor can’t talk to the printer’s software. That can happen for several reasons, such as wrong wiring, software settings, or damage to the BLTouch.

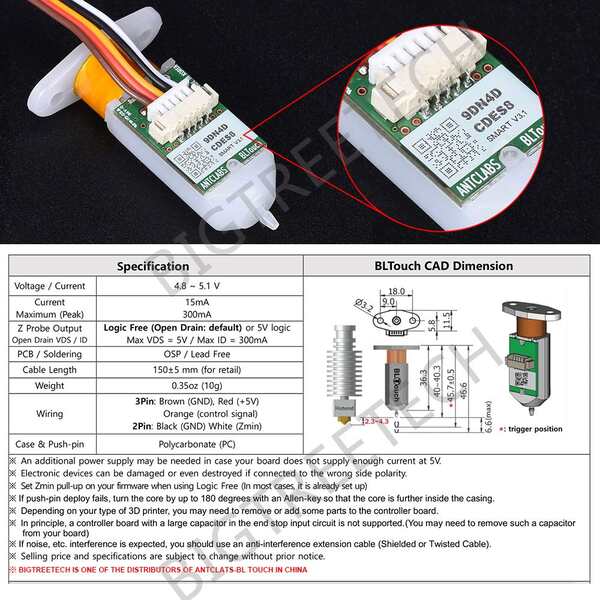

BLTouch Failed To Verify Sensor State — Image Source by Amazon

Common causes of the error

Several things can cause the problem BLTouch failed to verify sensor state. Some of the most frequent reasons are:

- Wwire that isn’t right: The BLTouch sensor is susceptible to wire that isn’t right. If you don’t connect the lines right, the sensor won’t be able to talk to the printer’s software.

- Wrong firmware settings: The printer’s software must be set up correctly so the BLTouch sensor works. If you have the settings right, the monitor will work right.

- Damage to the BLTouch’s physical parts: The BLTouch sensor is fragile. It may be unable to communicate with the printer’s software if broken.

Read Also: How The Devos Light Ranger Enhances Your Camping Experience

How to fix the error

If you get the problem message BLTouch failed to verify sensor state, you can try a few things to fix it.

Check the connections: You should start by checking the wires. Ensure the wires are linked to the BLTouch sensor and the printer’s mainboard in the right way.

Switch out the software: If the connection is correct, you may need to change the software on the printer. The problem you are having might be fixed in the latest version.

Switch out the BLTouch: If the wires and software are correct, you may need to change the BLTouch sensor. The monitor might be broken and unable to work right.

Image source by Amazon

Best way to avoid the recurrence of the error:

Follow these steps to avoid getting the error message BLTouch failed to verify sensor state again:

- Make sure the wires are correct.

- Make sure to update the software.

- Carefully handle the BLTouch sensor.

Learn which sensors your 3D printer will use.

We have a variety of levelling gauges that will make it easy for you to print.

Microswitch + Radio Controlled Servo: The Traditional Method

A servo motor with a microswitch is used in this tried-and-true way. As the tool carriage moves up or down along the Z axis, the servo arm moves out to touch the print bed. When the microswitch is turned on, exact readings can be made. Even though this method works, smaller extruder wheels may be unable to use it.

An inductive sensor is accurate and lasts a long time – Electromagnetic inductance is used by inductive devices to find metal items. These gauges that don’t touch anything are accurate and always give solid results. They work with metal beds and don’t have any working parts, so that they will last a long time. Even though they may be more expensive, their accuracy is worth the cost.

A capacitive sensor is flexible and works with many things – Capacitive sensors can work with various bed materials, such as glass, metal, and plastic. They measure the capacitance and give exact results when they are close to a surface. But they are sensitive to changes in temperature and humidity, so the z-offset needs to be changed when the bed surface changes.

BLTouch Failed To Verify Sensor State — image source by Amazon

How to Install the BLTouch?

Prepare your printer first. Unplug your printer. Remove the print bed and the Z-axis endpoint.

Please install the BLmTouch. You can find various mounting brackets for the BLTouch. Please be sure you choose a printer-compatible option.

Please install the BLTouch in the location you prefer.

Make sure to connect the wires of the BLTouch. The BLTouch has four wires: red, black, white, and blue.

Attach the wires to the correct ports on the printer’s mainboard.

Please ensure that you update the firmware of the printer. To use the BLTouch, you’ll need a firmware that is compatible with it. You can visit the BLTouch website to download the firmware. Please update the firmware on the printer’s mainboard.

Read Also: Lithophane Night Lights: A Beautiful And Unique Way To Light Up Your Home

Could you please calibrate the BLTouch?

After updating the firmware, it is necessary to calibrate the BLTouch. It will ensure that the sensor is working correctly. There are various methods available for calibrating the BLTouch. You can refer to the instructions with the sensor or find a tutorial online.

Image source by Amazon

Initial Check Up

When retracted, the BL-Touch probe should be mounted properly, around 2 mm above the nozzle.

- The probe should run a self-test when the printer is turned on, with the pin moving up and down. The red LED should be on after the self-test.

- If the probe is blinking red or the pin is pointing down instead of up, check the connections and turn off the printer.

- Test the probe’s response to firmware commands by typing “BLTOUCH_DEBUG COMMAND=pin_down” in the printer terminal. The pin should slide down, and the red light should stop blinking.

- Ensure the red light returns when sending the command “BLTOUCH_DEBUG COMMAND=pin_up”. Problems exist if the light starts flashing.

- During the homing test, lightly tap the pin with a fingernail instead of contacting it to the print bed. If the printer doesn’t stop when touched, switch it off to prevent damage.

- Repeat the G28 command, but make sure the pin touches the floor instead of the bed this time.

- Use the Probe Calibrate manual to adjust the x, y, and z offset configuration settings. Verify that the Z offset is within 1mm.

- If the BL-Touch flashes red, issue the command “BLTOUCH_DEBUG COMMAND=reset” to force it out of an unstable state.

- If the calibration is thrown off, the pin may need to be repositioned using a ballpoint pen and the screw on the probe.

- If you get the “BLTouch failed to validate sensor state” error, set “pin-up touch mode reports triggered: False” in the device’s configuration.

BLTouch Failed To Verify Sensor StateImage Source by Amazon

Connecting the signal wire of a BL-Touch v3 to the Z end-stop pin on some printer boards can cause unexpected behaviour. Consider connecting it to a different pin or adding a hardware “pull-up resistor”.

To conclude, BLTouch is a great way to improve the accuracy of your 3D prints. Installing may seem complicated but with time and careful attention to detail. It is possible. This guide should help you install BLTouch on your printer. Yes, you may begin to take advantage of automated bed leveling.